BIA hydraulic buckets simplify the handling of bulk materials. Whatever the application – food, grain, soil, sand, gravel, rubble, snow – the BIA is easy to use! BIAs are the only hydraulic buckets made with ears and reinforcements running on all four sides. This makes the equipment indestructible and reduces maintenance to zero! To improve strength and performance, the double cylinder is standard on all models! All BIA models are universal for all types of forklifts and trucks.

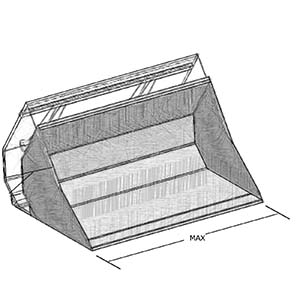

Max. capacity

1.700 lt.

Max. width

2.200 mm

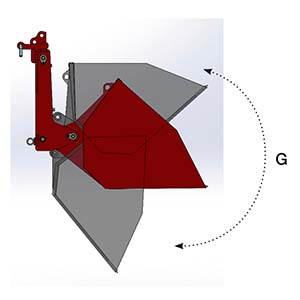

Max. width

90°

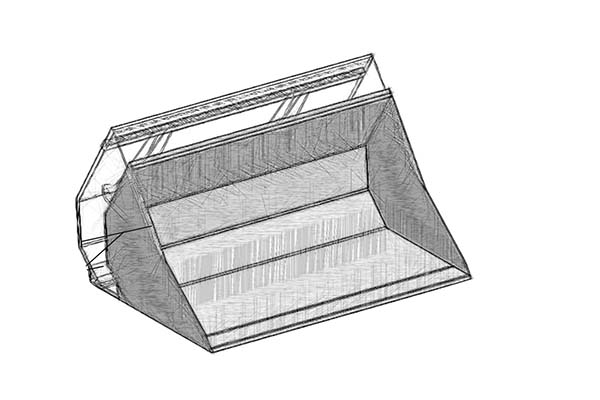

Doppia versione: standard e maggiorata

The hydraulic buckets are available in two versions: standard (BIA) and extended (BIA M). Thanks to the special folding of the bucket, the oversized version allows a larger capacity with a smaller footprint. BIA M is an ergonomic solution, designed to reduce space without sacrificing capacity.

Double cylinder, double advantage

To improve strength and performance, the double cylinder is standard on all models! Even on the smallest ones.

Universal!

All BIA models are quickly applicable to all types of forklift trucks thanks to specific attachments: FEM 2 or 3 for industrial forklifts, ears and bushings for tractor-mounted forklifts, 3-point attachment for the tractor, EURO for front loaders or telescopic handlers.

Combined couplings

We can make BIAs versatile! If the means of support are different, we can also make double attachments: e.g. FEM and three-point attachment.

Fields of application

Download data sheet

Field photo

Watch the video

FAQ

Service and customer relations

Our sales and after-sales department offers prompt responses to requests for quotations and order processing. Service is immediate and our large warehouse enables spare parts to be dispatched within 24 hours.

Attention to detail tailoring approach

We devote our efforts to producing a product that is reliable in all respects. We listen to the customer and offer the possibility of customising products.

Endurance, product durability and resistance

Our products are the most durable on the market: thanks to their specific strength and resistance. Maintenance is rarely required within the first few years of life.

Made in Italy, Italian manufacturing, passion

From the supply chain of materials to the choice of collaborators, we only work with qualified and certified Italian components. We want to enhance the value of the supply chain in our region.