Tecnoagri pruning bars make it possible to carry out maintenance work on public or private green areas quickly, safely and easily. They are proposed in 3 main lines with different characteristics and cutting widths: the KITE line with saw discs, SNIPE with SCHUMACHER teeth, COMMON with double-blade bars. All bars are applicable to any model of excavator, brushcutter and pruner.

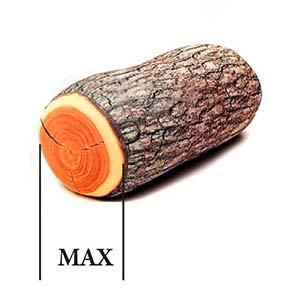

Max. cutting diameter

15 cm

Max. width

220 cm

Cutting tool

Discs or Teeth

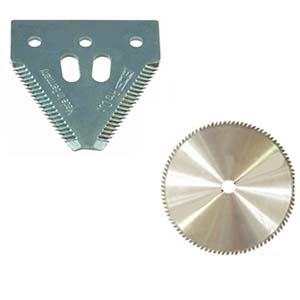

KITE 10

KITE 10 is the disc pruning bar suitable for small or medium power excavators or brush cutter arms. It is available in two versions, with a cutting width of 100 or 140 cm, and with 40 cm diameter saw discs. KITE 10 ensures a maximum cutting diameter of 8 cm. The required power supply is 40 l/min.

KITE 15 HD

KITE 15 HD is the disc pruning bar suitable for medium or high-powered excavators or brushcutter arms. It is available in three versions, with cutting width 165, 225, 275 cm, and with 60 cm diameter saw discs. KITE 15 HD ensures a maximum cutting diameter of 15 cm. The required feeding capacity is 90 l/min.

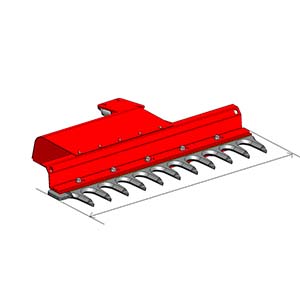

SNIPE

SNIPE is the SCHUMACHER tine-mounted pruning bar suitable for small to medium power excavators or brushcutter arms. It is available in four versions, with cutting widths of 120, 150, 180 and 200 cm. SNIPE ensures a maximum cutting diameter of 3 cm. The required power supply is 20 l/min.

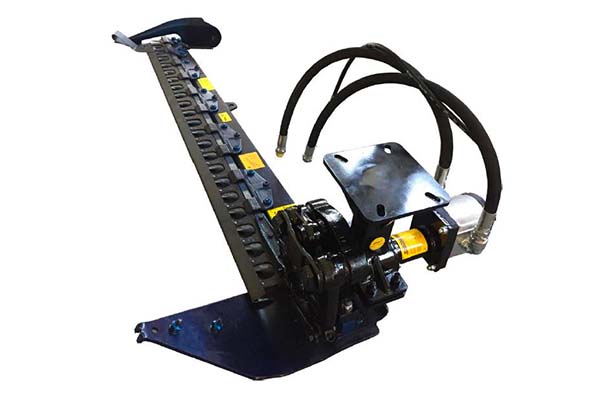

COMMON

COMMON is the twin-blade cutter bar suitable for small to medium power excavators or cutter booms. It is available in five versions, with cutting widths of 120, 167, 182, 197, 212 cm. SNIPE ensures a maximum cutting diameter of 3 cm. The required power supply is 55 l/min.

Fields of application

Download data sheet

Field photo

Watch the video

FAQ

Service and customer relations

Our sales and after-sales department offers prompt responses to requests for quotations and order processing. Service is immediate and our large warehouse enables spare parts to be dispatched within 24 hours.

Attention to detail tailoring approach

We devote our efforts to producing a product that is reliable in all respects. We listen to the customer and offer the possibility of customising products.

Endurance, product durability and resistance

Our products are the most durable on the market: thanks to their specific strength and resistance. Maintenance is rarely required within the first few years of life.

Made in Italy, Italian manufacturing, passion

From the supply chain of materials to the choice of collaborators, we only work with qualified and certified Italian components. We want to enhance the value of the supply chain in our region.